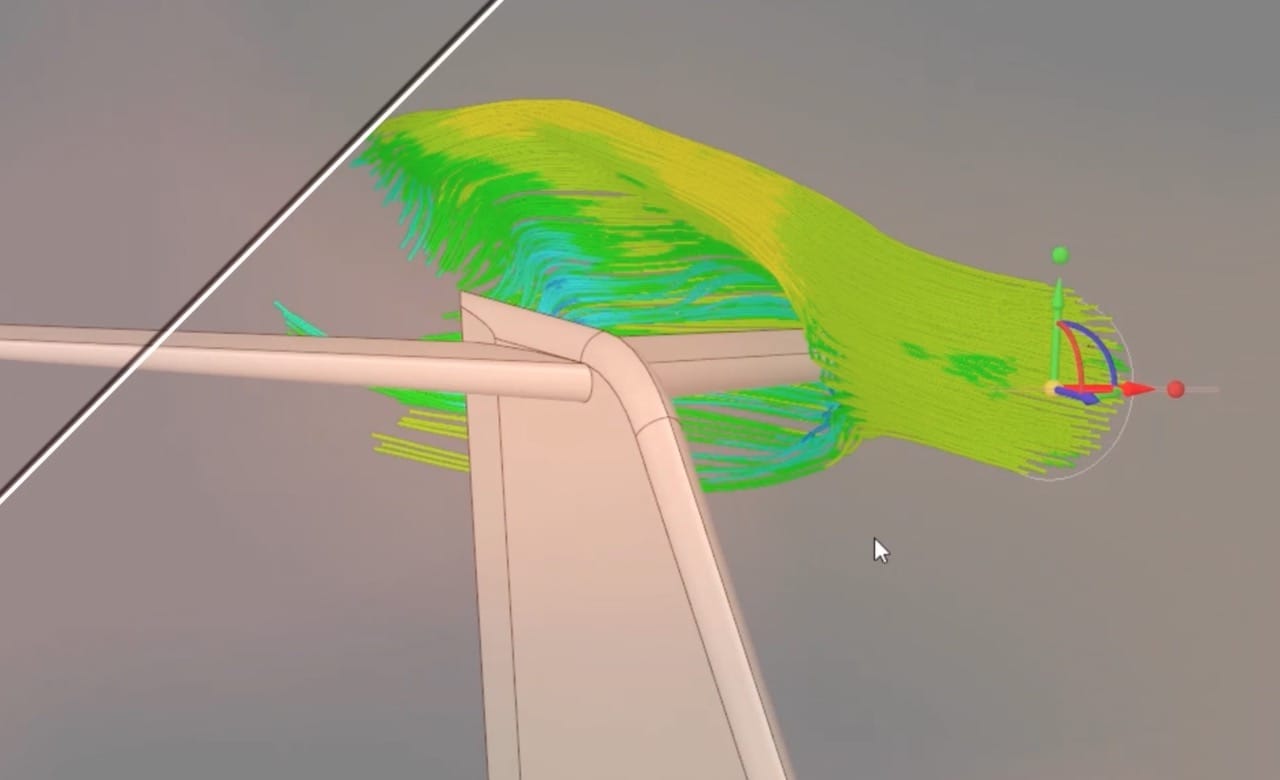

The proposed algorithms are implemented as the HollowTron webserver and are freely available from Voronoi Diagram Research Center. Here, spheroids are arranged by the Voronoi diagram of 3D ellipsoids and the tool path, including circular printing motions, is produced using the Voronoi diagram of circular 2D disks. Additionally, the resulting spheroidal hollows facilitate the circular printing motion of extruders using G2/G3-codes, which provide three critical advantages compared to the currently popular G1-code-based linear motion: shorter printing time, better printing quality, and smaller tool path file. In addition to reducing stress concentration through their inherently smooth boundaries, these spheroids require no additional support structure, when properly designed. Here, we introduce a novel support-free hollowing method that uses an arrangement of vertically-aligned prolate spheroids. This new module also extends SpaceClaim's intuitive interface, speed, and ability to work with any major 3D format into the 3D printing world.Extrusion-based printing frequently requires a hollowing step to remove material from inside of artifacts and subsequently reduce the amount of material, printing time, product weight, energy consumption, and ultimately, the cost.

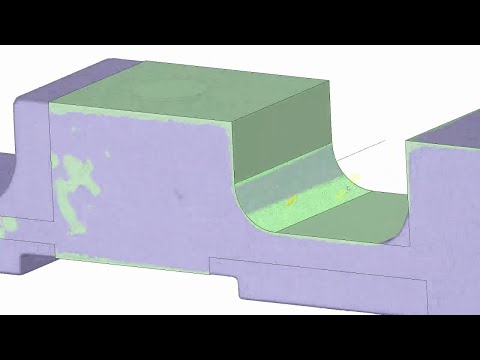

The STL Prep for 3D Printing module prepares models for 3D printing efficiently and easily by offering a single solution that not only repairs problems, but also modifies STL and CAD files. Edit mold geometry directly in the cross section.Quickly create mid-surface models for mold simulation.This video will illustrate the many benefits of using it as a geometry modeling tool. Combine STL models with other STL models or solids ANSYS SpaceClaim is a multipurpose 3D modeling tool that delivers faster engineering results.Automated verification and repairing STL: intersections, watertightness, misaligned normals, co-incident triangles, etc.Work directly with STL files to shell, scale, and split models.Split models for better printing, adding pins, lips, mortise, or joints as needed.Save money on expensive 3D printing software.Repair models from problems you typically run into during the printing process.

0 kommentar(er)

0 kommentar(er)